Contract manufacturing involves a contract between a company and a manufacturer to produce a specified volume of goods. The manufactured goods maintain all the design characteristics, formulas, and specifications provided by the company, along with the company’s branding and labeling.

Contract manufacturing may be used as a method to produce entire products for a brand or simply to outsource certain components that are beyond an OEM’s capability or capacity.

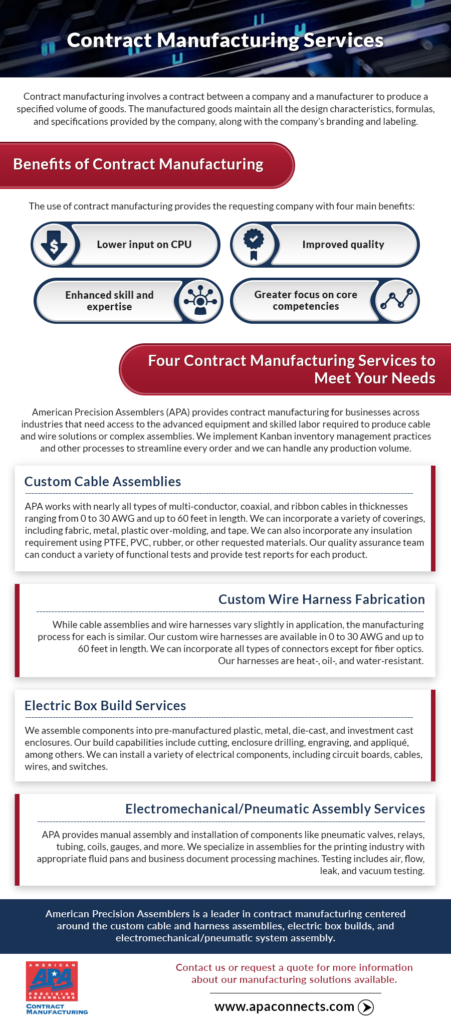

Benefits of Contract Manufacturing

The use of contract manufacturing provides the requesting company with four main benefits:

- Lower input on CPU. Using contract manufacturing helps many companies lower their cost per unit since there is no capital investment in manufacturing equipment or capabilities. Contract manufacturers also buy materials in bulk, which enables additional savings that can be passed on to customers.

- Improved quality. A good contract manufacturer should implement stringent quality assurance procedures into their manufacturing processes. This often includes testing and monitoring equipment that the customer may not otherwise have access to.

- Enhanced skill and expertise. Hiring a contract manufacturer gives the customer company access to skilled labor that may otherwise be difficult to find or access.

- Greater focus on core competencies. Contract manufacturing takes the burden of production off the shoulders of the hiring company, allowing the hiring company to focus on core competencies such as sales, marketing, product development, and more.

Four Contract Manufacturing Services to Meet Your Needs

American Precision Assemblers (APA) provides contract manufacturing for businesses across industries that need access to the advanced equipment and skilled labor required to produce cable and wire solutions or complex assemblies. We implement Kanban inventory management practices and other processes to streamline every order and we can handle any production volume.

Custom Cable Assemblies

APA works with nearly all types of multi-conductor, coaxial, and ribbon cables in thicknesses ranging from 0 to 30 AWG and up to 60 feet in length. We can incorporate a variety of coverings, including fabric, metal, plastic over-molding, and tape. We can also incorporate any insulation requirement using PTFE, PVC, rubber, or other requested materials. Our quality assurance team can conduct a variety of functional tests and provide test reports for each product.

Custom Wire Harness Fabrication

While cable assemblies and wire harnesses vary slightly in application, the manufacturing process for each is similar. Our custom wire harnesses are available in 0 to 30 AWG and up to 60 feet in length. We can incorporate all types of connectors except for fiber optics. Our harnesses are heat-, oil-, and water-resistant.

Electric Box Build Services

We assemble components into pre-manufactured plastic, metal, die-cast, and investment cast enclosures. Our build capabilities include cutting, enclosure drilling, engraving, and appliqué, among others. We can install a variety of electrical components, including circuit boards, cables, wires, and switches.

We use appropriate automotive testing systems, machinery, and sub-systems for quality assurance. APA also provides reverse engineering, value engineering, and manufacturing improvements as required.

Electromechanical/Pneumatic Assembly Services

APA provides manual assembly and installation of components like pneumatic valves, relays, tubing, coils, gauges, and more. We specialize in assemblies for the printing industry with appropriate fluid pans and business document processing machines. Testing includes air, flow, leak, and vacuum testing.

Contract Manufacturing Services at American Precision Assemblers

Contract manufacturing allows companies to take advantage of the facilities, equipment, and expertise of the contract manufacturer without increasing cost per unit, reducing quality, or investing in manufacturing equipment and expertise.

American Precision Assemblers is a leader in contract manufacturing centered around the custom cable and harness assemblies, electric box builds, and electromechanical/pneumatic system assembly.

Contact us or request a quote for more information about our manufacturing solutions available.